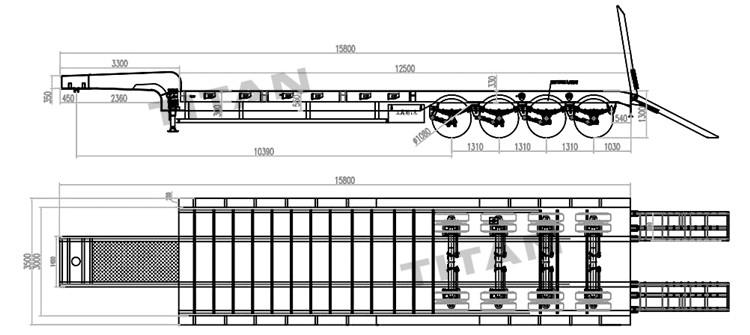

4 Axle 100 Ton Lowbed Truks for Sale in Nigeria

Nigeria customer bought TITAN’s 4 axle 100 ton lowbed trucks for sale. This is not the first time the customer has purchased TITAN’s lowbed truck trailer. The 4 axle lowbed truck was purchased by the customer for the local friend. His friends like TITAN's design and use. Nigeria customer mainly transport large-scale machinery and equipment, and we recommend the most suitable 4 axle 100 ton lowbed trucks for them. And buy two units at once to save on shipping cost.

Below is a picture of the packaged and shipped.

Package of 4 Axle 100 Ton Lowbed Truks for Sale

TITAN lowbed trucks main beam adopts HG60 High Strength Steel Material

- HG60 steel has high yield strength, more durable and stronger than ordinary steel, and its loading capacity is 5 times more than the lowbed truck which is built by Q345 steel. - Each ton of HG60 high strength steel costs double the price of ordinary Q345 steel material, ensuring that our TITAN lowbed trucks for sale will have a long service life and to avoid unnecessary maintenance costs.

Other factories lowbed truck trailer

- The yield strength of Q345 steel is just 345Mpa, so it can not meet the high loading capacity requirements and the main beam of the 4 axle lowbed truck trailer would be broken when the excavator trailer is overloading.

- Q345 steel is low-cost steel, with short service life, increase maintenance costs and also can not meet load requirements on different kinds of roads.

4 Axle 100 Ton Lowbed Truks for Sale in Nigeria

it is important to ensure that your lowbed truck trailer operates at its optimal level at all times. This is only possible if you know how to conduct control of a low bed trailer. Quality control involves checking the performance of various components.

Welding inspection

Welding all the lowbed trailer for sale beams and plates is cumbersome. Many mechanics take short cuts in this process. Hence, you must be careful when inspecting the welded parts and joints.

All the 100 ton lowbed truck for sale welded parts should be smooth and uniform. Sometimes welding leave some rough surfaces because of heat deformation. Check all the joints for rough surfaces. Another thing to look out for when inspecting welded parts is cracks and penetration to adjacent beams.

If the manufacturer is not careful with the welding process, the welding machine can penetrate through the steel plate or cause cracks. Such deformations will reduce the strength of the beams.

Welding is the most important part of manufacture process. Welding Procedure Specification is a strict standard to keep the high quality of the trailers.

Details of 4 Axle 100 Ton Lowbed Truks for Sale in Nigeria

Fastener inspection

The main reason for fastener inspection is to ensure that all fasteners are tight. A fastener can be loose if it was not fixed properly or if the dimensions are wrong.

Hence, you need to determine if the fastener requires to be tightened or replaced with another fastener with the right measurements. You need tight fasteners for the strength and stability of the trailer especially when it fully loaded.

Load test of 4 axle lowbed trucks for sale

Manufacturers give the loading capacity of each trailer but you cannot rely on that information alone. You need to test if the trailer can handle the maximum load as specified by the manufacturer.

Inspect the process of loading the cargo on the lowbed trucks for sale to ensure that the ramp is working properly. If the 4 axle lowbed truck has the loading capacity as specified, it should be easy to load and transport heavy cargo with the trailer.

You can download video, you can learn about different types of lowbed semi-trailers, like 2axle, 3axle, 4axle lowbed semi trailer, hydraulic ladder lowbed semi trailer, etc. As well as the process, testing, packaging and customer feedback, etc.

Welcome to download our quotation, if you have other questions, please contact us

Welcome to download our quotation, if you have other questions, please contact us