Table of contents

Chapter 1: What is a removable gooseneck trailer?

1.1: How much weight can a removable gooseneck hold?

1.2: How long is a removable gooseneck trailer?

Chapter 2: What are the benefits of a removable gooseneck?

2.1: What would you load on a removable gooseneck?

Chapter 3: What are the characteristics of a removable gooseneck trailer?

Chapter 4: How do you load a removable gooseneck trailer?

A removable gooseneck trailer is a type of heavy-duty trailer used for transporting large and heavy equipment. The neck of the removable gooseneck trailer can be detached from the main deck, allowing the front of the trailer to be lowered to the ground for loading and unloading. This feature makes it easier to load and unload heavy equipment such as bulldozers, excavators, and other construction machinery. Once the equipment is loaded, the removable gooseneck trailer is reconnected to the truck and hauled to its destination.

4 Axle 120 Ton Removable Gooseneck Trailer Loading Test in Factory

The weight that a removable gooseneck trailer can hold depends on various factors such as the specific design and construction of the gooseneck, the capacity of the removable gooseneck trailer for sale it is attached to, and the weight distribution of the load being carried. It is important to consult the manufacturer's specifications and guidelines to determine the maximum weight capacity of a particular gooseneck.

TITAN can be customized removable gooseneck trailer according to actual load requirements. Common design load tonnages are 60 tons, 80 tons, 100 tons, 120 tons, 150 tons, fixed max weight reaches 200 tons.

The length of a removable gooseneck trailer can vary depending on the manufacturer and model. Removable gooseneck trailers typically range in length from 12m to more than 18m, with most falling between 14m and 16m long. The specific length of a particular trailer will depend on factors such as its intended use, weight capacity, and other design considerations.

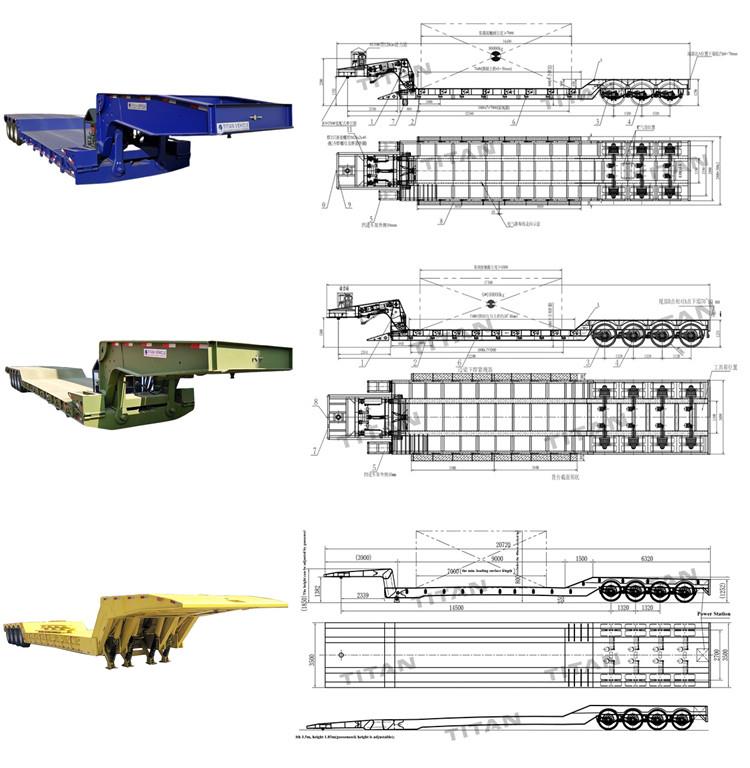

3/4 Axle Removable Gooseneck Trailers and Folding Gooseneck Trailer

3/4 Axle Removable Gooseneck Trailers and Folding Gooseneck Trailer

There are several benefits to using a removable gooseneck trailer for transporting heavy equipment and machinery:

Versatility: Removable gooseneck trailers are versatile and can transport a wide variety of heavy equipment, machinery, and other large items.

Easy loading and unloading: The detachable front end of the trailer allows for easy loading and unloading of heavy and oversized items. The loaded items can be driven onto the trailer or lifted onto it using a crane.

Reduced height: The gooseneck design allows for a lower deck height than other types of trailers, which is especially beneficial when transporting tall or oversized loads that need to clear bridges or other obstacles on the road.

Increased payload capacity: The reduced height of the trailer deck also increases the available vertical space, allowing for taller loads and maximizing the payload capacity of the trailer.

Improved safety: Removable gooseneck trailer for sale typically have a low center of gravity, which makes them more stable and less prone to tipping over on uneven terrain or sharp turns.

Cost-effective: Because of their versatility and high payload capacity, removable gooseneck trailers can be a cost-effective option for transporting heavy equipment and machinery as they can often transport more items at once, reducing the number of trips needed and ultimately saving time and money.

Overall, the benefits of a removable gooseneck trailer make it a popular choice for transporting heavy equipment and machinery across different industries.

Removable Gooseneck Trailer in TITAN Factory

A removable gooseneck is a type of trailer that is designed to transport heavy equipment and machinery. Common items that are loaded on a removable gooseneck trailer include construction equipment such as bulldozers, excavators, backhoes, cranes, and other heavy machinery used in building and construction projects.

Additionally, agricultural equipment, such as tractors, combines, and harvesters, can also be transported using a removable gooseneck. Other possible loads could include large industrial components, like oil and gas drilling equipment, structural steel, or prefabricated modular housing units.

Ultimately, the specific items that are loaded onto a removable gooseneck trailer depend on the needs of the transportation project.

Removable Gooseneck Trailer is in Production

A removable gooseneck trailer is a specialized type of trailer commonly used for transporting heavy equipment. Here are some of its key characteristics:

1. Removable Gooseneck: The trailer has a detachable front end that can be removed to allow the cargo to be loaded onto the removable gooseneck trailer from the front.

2. Low Platform: Due to the low ground clearance and low longitudinal beam height of this kind of removable gooseneck trailer for sale, the load-bearing surface is 300-400mm lower than that of the normal concave-center removable gooseneck trailer, thereby effectively reducing the height of the center of gravity of the loaded goods and improving the stability during transportation.

3. High Capacity: The construction of the trailer is typically very robust, allowing it to handle heavy loads with ease. Removable gooseneck trailer's main beam of TITAN is made of HG60 high-strength structural steel. The yield strength of HG60 steel is ≥ 620MPa, which is more durable and stronger than ordinary steel.

4. Versatility: The removable gooseneck design allows the trailer to be used for a variety of different cargoes, including heavy equipment like bulldozers, excavators, and cranes.

5. Efficient: Because this type of model eliminates the rear ladder, the bearing surface can be lengthened, and because the construction machinery does not go from the rear, the slope angle in front of the bridge can be appropriately increased, so that the bearing surface can be lengthened. The length of the low flat cargo table with a ladder at the end is longer, which can effectively load more loads, indirectly improve the loading efficiency, and create greater benefits for users.

6. Safety: The low profile and sturdy construction of the removable gooseneck trailer provide added safety benefits when transporting heavy equipment or oversized loads.

Removable Gooseneck Trailers Ready to Ship

Uncoupling for Loading

During coupling and uncoupling, the removable gooseneck trailer assembly is let to a lowered position. During uncoupling, the safety pin handle gets puled and locked open to let the safety pin detach the T-bar yoke free from the yoke pocket. The control lever for the hydraulic ram feature on the other hand is maneuvered to provide hydraulic pressure fluid inside the dram in order to lift the thrust blocks somewhat clear off their sitting positions on the main beam.

After achieving this, the lock finger gets retracted and the crank handle then is swung in an upward manner to anchor the safety hooks and the thrust blocks upwardly. Once this is attained, the lever is then locked in position through the lock finger that is fit in an upper coupling hole for the same.

Next, the hydraulic ram feature gets extended further to facilitate a further gooseneck rotation with respect to the removable gooseneck trailer for sale. This is done to facilitate the withdrawing of the two lock pins that are engaged with the hooks.

The pins get swung in an upward manner through the use of the crank handle. On achieving this, the hydraulic pressure in the ram gets reversed hence allowing the pressure to go down in the cylinders’ bottom chamber. This action slowly lowers the gooseneck and the trailer bed to the ground. You can choose to place a removable support block in between the trailer frame and the gooseneck beam in order to keep the gooseneck slightly off the ground surface. It is at this point when you can move the tractor away in order to give room for loading.

Click the picture below to watch our operation explanation

Coupling for Transportation

Once your cargo has been safely loaded on the removable gooseneck trailer, it is time to reconnect the gooseneck and the trailer bed ready for transit. Basically, this is a reverse procedure of the uncoupling operation.

First, the operator needs to reverse back to the trailer bed location. Ensure that the coupling hooks are set in position to facilitate easy engagement.

The forward section of the trailer bed has a forwardly swerving entryway to make the hooks align with their attaching positions. When the T-bar yoke is perfectly aligned with the yoke pocket, fluid pressure can now be supplied to the hydraulic cylinders’ top chambers.

This forces the piston rods downwards hence driving the T-bar yoke directly into the pocket. The safety pin is then inserted to ensure a positive link between the pocket and the T-bar yoke. More hydraulic pressure is supplied into the cylinders to move the trailer bed and the gooseneck in an upward direction.

The trailer bed should be moved to reach a position higher than its horizontal operating level to facilitate the moving of the lock pins into their perfect locking position. Once this is achieved, the hydraulic rams are then retracted back to allow the trailer bed and the gooseneck to descend.

The next thing is to move the safety hooks and the thrust blocks downward into an engaging position to lock them in place. After that, the fluid pressure in the rams is then reversed moderately. This provides a hydraulic interlock that holds the thrust blocks tightly in place. Once this is done, the removable gooseneck trailer for sale assembly is now ready for over the road transportation.