Table of contents

Chapter 1: What is The Point of a Lowboy Trailer?

Chapter 2: Lowboy Trailer Dimensions

Chapter 3: Types of Lowboy Trailers

Chapter 4: Pros and Cons of Using a Lowboy Trailer

Lowboy trailer in Philippines is a type of semi trailer that is designed to transport heavy and oversized equipment or machinery. The main advantage of a lowboy trailer is its low deck height, which allows for taller cargo to be transported without exceeding height restrictions on roads and bridges. The low deck height also makes it easier to load and unload heavy equipment, as it can be driven onto the trailer without the need for a ramp or crane. Additionally, lowboy trailers often have removable goosenecks, which allow for easier loading and unloading of equipment. Overall, the point of a lowboy trailer is to provide a safe and efficient means of transporting heavy and oversized equipment.

The detachable gooseneck lowboy trailer is a whole, and the components are fixedly connected without relative movement. The mechanical gooseneck itself does not have a height adjustment function. When connected to a lowboy trailer, it relies on a modified tractor frame to provide the required adjustment slope. The disassembly and assembly process of the gooseneck of a mechanically detachable lowboy trailer often requires moving the tractor back and forth several times to complete, so it is not suitable for short-distance transportation.

The dimensions of lowboy trailers can vary depending on their specific design and regulatory guidelines. However, here are some general dimensions you may come across:

1. Deck Length: The deck length typically ranges from 24 feet to 29 feet (7.3 meters to 8.8 meters) for a standard lowboy trailer. However, there are extendable lowboy trailers available that can be adjusted to accommodate longer cargo.

2. Deck Width: The deck width of a lowboy trailer is usually around 8.5 feet (2.6 meters). This width is designed to accommodate most standard-sized equipment and machinery. However, wider lowboy trailers may be available for specialized applications.

3. Deck Height: The deck height, also known as the ride height, refers to the distance from the ground to the top of the trailer's deck. It typically ranges between 18 inches to 24 inches (45 centimeters to 60 centimeters) for a standard lowboy trailer. However, specific height requirements may exist based on local regulations.

4. Overall Length: The overall length of a lowboy trailer, including the gooseneck and rear ramp, can range from around 40 feet to 53 feet (12.5 meters to 16.2 meters) for a standard configuration. However, specialized models may have different overall lengths.

5. Maximum Payload Capacity: Lowboy trailers are designed to transport heavy loads, and their maximum payload capacity can vary. It depends on factors such as the trailer's construction, axle configurations, and government regulations. Common payload capacities for lowboy trailers range from 40 tons to over 150 tons.

It's important to note that these dimensions are approximate and can vary based on manufacturer specifications, regional regulations, and specific trailer configurations. When selecting a lowboy trailer for transportation needs, it's essential to consider the size and weight of the equipment being transported to ensure compliance with regulations and safe transportation practices.

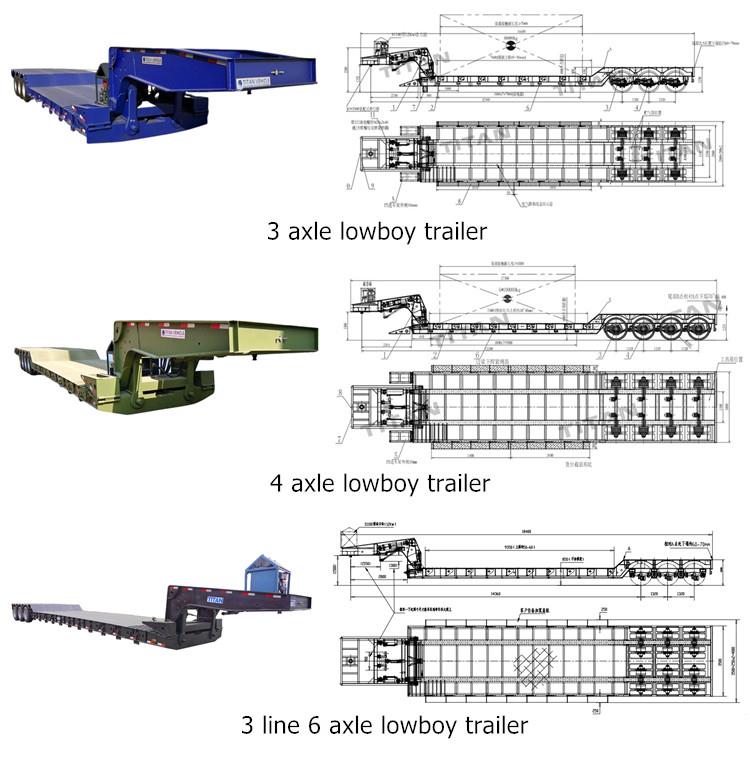

1. Removable gooseneck lowboy trailer:

These trailers are widely used in the heavy transportation industry and are the most common type of lowboy trailer. The removable gooseneck lowboy trailer uses hydraulic cylinders to remove the gooseneck. When loading, the lowboy trailer can be lowered and raised as needed.

2. Folding lowboy trailer:

The gooseneck is a design with a hydraulic folding structure. When the structure folded, it’s a gooseneck to connect the trailer with the prime mover. When it unfolded, it’s will touch the ground as a shallow slope for cargos loading. Compare to rear ramps, it’s shallow and stable, could effective solutions for cargo loading.

3. Fixed gooseneck lowboy trailer:

This type of lowboy trailer has a fixed front section called a gooseneck, which attaches to the truck tractor. The gooseneck is designed to distribute weight evenly and facilitate easy loading and unloading of heavy equipment.

4. Stretch Lowboy Trailer:

Stretch lowboy trailers are designed to be extendable, allowing for the transportation of longer equipment. The trailer can be adjusted to accommodate varying lengths, offering flexibility for oversized loads.

While we’ve briefly discussed some of the types of lowboy trailers and their functions, there are countless other reasons to consider using a lowboy trailer for your next haul.

Advantages of lowboy trailer

1. Height Clearance: Lowboy trailers have a lower deck height, enabling them to transport tall cargo that may not fit under standard trailers or bridges. This makes them ideal for hauling oversized equipment or machinery.

2. Stability: The lower deck height and design of lowboy trailers provide enhanced stability during transportation. This helps to minimize the risk of cargo shifting or tipping over, especially when transporting heavy or unevenly distributed loads.

3. Versatility: Lowboy trailer in Philippines can be customized to accommodate various cargo types and sizes. They often feature removable goosenecks, extendable deck lengths, and adjustable axles, allowing for flexibility in transporting different types of equipment.

4. Maneuverability: Lowboy trailers are designed with a lower center of gravity, contributing to improved maneuverability. This can be beneficial when navigating tight spaces or difficult terrains, such as construction sites or uneven roads.

5. Weight Capacity: Lowboy trailers are engineered to handle heavy loads. They typically have higher weight capacities compared to other types of trailers, making them suitable for transporting large and weighty machinery or equipment.

Overall, lowboy trailer in Philippines offer practical advantages for industries that require the transportation of oversized or heavy cargo, providing safe and efficient options for moving specialized equipment.

Disadvantages of lowboy trailer

1. Cost considerations: Lowboy trailers are typically more expensive to purchase and maintain compared to standard trailers. Their specialized design and construction require higher manufacturing costs, and maintenance and repair expenses can also be higher.

2. Freight Limitations: Due to weather conditions, a lowboy trailer may not be best to ships electronics, home furnishing, or perishable items. There may also be a need to keep the temperature of the cargo regulated which you don’t get with a lowboy trailer in Philippines.

3. Skill Difficulty: Transporting big loads necessitates special handling and hauling abilities. Even securing the load can be hazardous when connecting straps and chains onto the load.